Machine enclosure

Machine enclosures reduce noise and vibration from production facilities, which improves the working environment and protects employees’ hearing. With tailor-made solutions, the noise level can be controlled effectively, without compromising the functionality of the machine. Ideal for companies that want optimal noise reduction and safety..

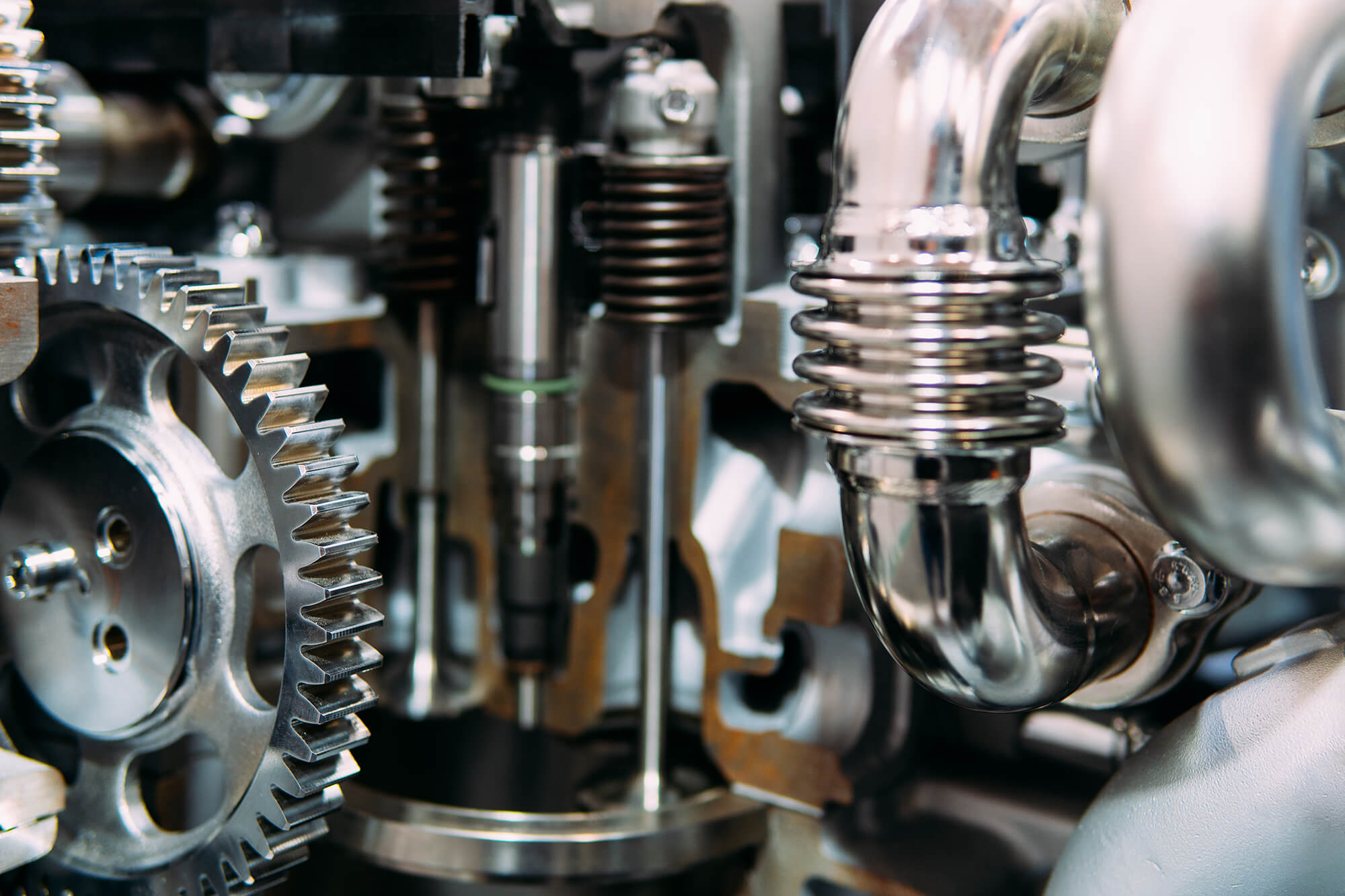

Enclosure of machinery, production equipment and robots

Enclosure is generally an effective method of noise reduction. You can encapsulate parts of a machine, or the entire machine.

Our MATADOR enclosures can provide sound attenuation up to 50 dB, which is perhaps the best on the market.

Encapsulating machines requires thorough preparation, all too often poor preparation is the reason why noise reduction is not optimal.

The biggest challenge is the openings that the enclosure must have for the entry and exit of materials.

We have 35 years of experience and have encapsulated over 1,000 machines, production plants and robots, in virtually all industries. See more here

Or contact us if you want to know more about encapsulation.

When vibrations cause problems

Vibrations from machines can propagate through floors and other building parts, and can cause nuisance even in remote buildings.

So-called vibration isolation can therefore be a necessary prerequisite to ensure that noise problems do not arise in neighboring buildings.

Correct insulators can usually be selected based on simple assessments.

Basically, there must be no fixed connection that can transmit sound from the machine to the surroundings.

If production premises are located close to canteens, offices or other noise-sensitive areas, you should pay extra attention to vibration insulation.

In other cases, e.g. very large machines can even cause walls and floors to crack.

Even small vibrations in buildings can be disruptive to precision work, e.g. accurate scales and other measuring equipment.

However, transmission to the floor can sometimes be so violent that it is a direct nuisance to the people who operate the machine.

The vibration isolation is carried out by installing elastic elements between the machine in question and the building, which inhibit the transmission of vibrations.

In practice, vibration isolation is carried out by placing the machine on vibration isolators, i.e. spring elements, which are usually made of rubber or steel.

When setting up machines on insulators:

- Assess the stability of the floor/substrate and determine the optimal location of the machine on the floor/substrate. An independent foundation may be necessary

- Certain machines can be advantageously placed on frame construction

- The total weight and the location of the center of gravity are determined for the machine and possibly frame. The weight of each support point should be evenly distributed over the support points

- The frequency of the machine’s vibrations is determined

- Degree of insulation is determined for the set-up

- Appropriate insulators are selected

- Axles, cable transfers, etc. are made elastic

Read more about vibration here

Contact us if you want to know more about vibration damping.

A machine can be sound proofed from the inside

Interventions can be made in various places when it needs to be noise dampened.

Relatively simple measurements can help to locate where the noise is coming from.

It is the responsibility of the supplier of the machine to ensure that it is properly soundproofed from the inside.

There is a sea of rules and methods for this work, and will be too extensive to deal with here.

You can find more information about noise reduction of the machine from the inside here

But you are always welcome to contact us if you want to know more.