Strategy for noise management

Our strategy for noise management is based on practical experience since 1989 and extensive knowledge in noise reduction and acoustics. The purpose of our learning center is to give you a solid insight and overview through general descriptions, rules of thumb, tips and recommendations. If you are faced with a specific project, you are always welcome to contact us for a non-binding conversation.

What is noise reduction and acoustics?

Despite many years of focus from both the authorities and the social partners, noise remains a challenge in many workplaces. Noise reduction and acoustics are about reducing unwanted sound and creating a pleasant sound environment, especially in workplaces where noise can be a challenge.

In most of the EU there is agreement that noise limits for different categories and industries should be observed, including a limit value of 85 dB(A) for the highest category, which MUST be observed. dB(A) is weighted noise measured in decibels over an 8-hour period, also known as LAEQ.

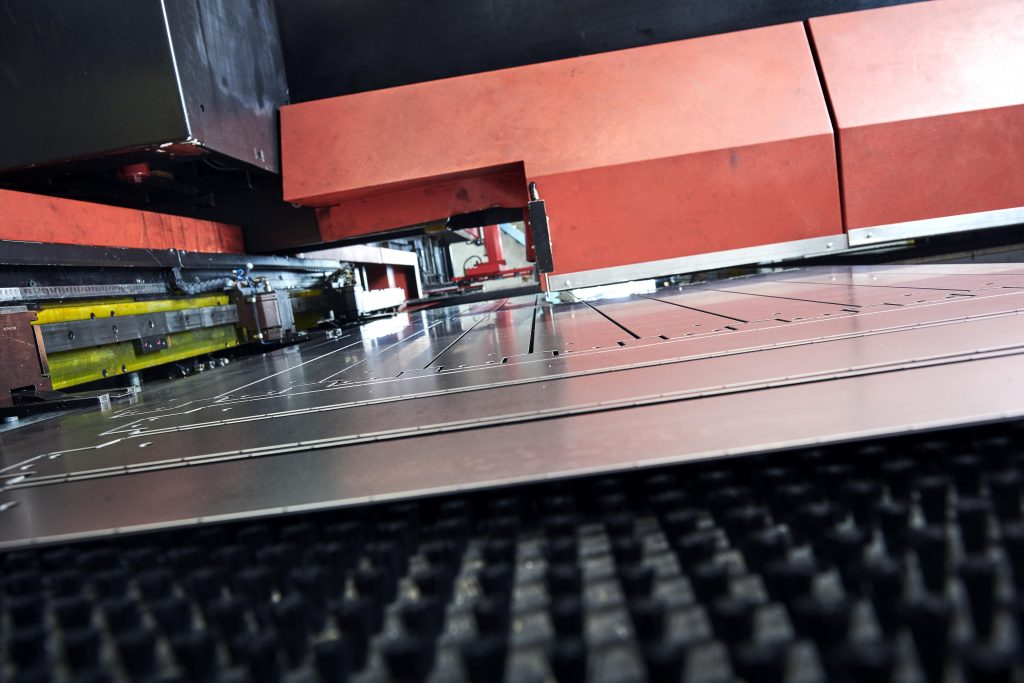

Machine enclosure with an acoustic ceiling and plenty of access via doors and gates.

Short animated video on noise reduction.

Short video on noise reduction.

When purchasing machines

There is no legislation on how much noise a machine may make, but it is legislated that the supplier must indicate how much noise the machine makes.

This is described in the Machinery Directive, and it follows that the noise level must be disclosed:

If the sound pressure level exceeds 70 dB(A) in the operator’s position

If the peak value of the sound pressure level exceeds 130 dB(C)

If the sound power level at the workplace exceeds 85 dB(A)

The European CEN has determined how these measurements must be made for a wide range of machine types. If the machine type is not found, the supplier must choose a relevant measurement method himself.

The supplier’s stated noise levels appear in the machine’s user manual.

Use of noise data from the user manual

The data in the user manual can be used with some caution in assessing the machine’s noise levels, however it should be noted:

Are the operating conditions at your place the same as those used during the supplier’s measurement of noise?

Is the measurement of noise defined by CEN, or has the supplier himself chosen how it is measured?

Is the room/room where the machine is to be placed at your place comparable to the room the supplier has measured in?

Do you use the machine in the way it is normally used, cf. the supplier?

Normally, however, the data in the user manual can be used to compare the noise levels of different machines.

We therefore recommend a certain safety margin, of e.g. 5 dB. That is that you should require a noise level that is 5 dB below the user manual data.

The supplier must demonstrate that the requirements have been met, preferably with an unbiased noise measurement, and this must be stated in the purchase contract.

When workspaces need to be furnished

When workspaces are to be furnished, it is crucial to prevent noise problems through appropriate design and furnishing of the room. This can be achieved by taking into account several factors, such as the location of noisy machinery, the use of sound screens, acoustic regulation, sound insulation and the management of noise from fixed building installations.

The construction process: The noise conditions at the workplace should be taken into account from the start in both remodeling and new construction. In this way, you can ensure an acceptable sound environment with the fewest possible resources, without compromising other considerations, such as architectural solutions.

A construction process can be simplified into four phases: planning, design, execution and inspection/acceptance.

Planning: In the planning phase, what is to be built and what the prerequisites are are determined. The quality of the acoustic solutions must already be defined here. It is important to set requirements for building layout, acoustics, sound insulation and technical installations and to ensure that the security organization is involved from the start. External experts should also be involved where necessary. The Norwegian Working Environment Authority’s guidelines and checklists can be useful resources, and it is important that consulting engineers and architects ensure that acoustics and sound insulation are integrated into the chosen solutions. The tender material should also include requirements for acoustics and sound insulation as well as methods for measuring these.

Design: In the design phase, the technical solutions are concretized, and since this phase is often carried out by the external supplier who has won the tender, it is important that your company participates actively in the discussions to ensure that acoustics and sound insulation are correctly implemented.

Execution: During the execution phase, supervision must be carried out to ensure that all noise conditions for the building are complied with. Even small defects, such as a poor seal, can significantly degrade sound insulation.

Control and approval: In this phase, the construction is approved, and it is important to check that the requirements for both acoustics and sound insulation have been met.

You can read more about the design of the workplace here, or contact us if you want to know more about the design of the workplace.

When noisy machines need to be installed

When noisy machines are to be installed, it is important to place them appropriately to minimize the noise. To achieve this, noisy and quiet activities should be separated as much as possible. We recommend the following principles:

Distance: Place noisy machines as far away as possible from other activities. When the room is properly acoustically damped, the sound pressure can be reduced by 10-15 dB over a distance of 10 metres.

Concentration: Gather the noisy machines in one place. This reduces the overall sound pressure in the rest of the room, although the sound pressure will be higher close to the machines.

Shielding: Use shelving, storage, or other physical barriers between noisy and non-noisy activities. The larger and denser these screens are, the more effective they are at reducing noise.

Absorption: Place noisy machines against walls and in corners where there is good sound absorption. This helps to reduce the radiated sound and makes it easier to shield the machine effectively. However, it is essential that walls and ceilings have good absorption, as poor absorption can worsen the noise.

Let Skov Industri help your company with a strategy for noise management

At Skov Industri, we are dedicated to helping you create a quieter and more comfortable working environment. With our many years of experience and extensive expertise in noise reduction and acoustics, we can offer tailor-made solutions to suit your specific needs. Whether you are faced with the purchase of machinery, the remodeling of a workspace or the development of a noise strategy, we are ready to advise and support you throughout the process.

We understand the importance of effective noise management and are here to ensure that your employees can work in optimal sound conditions. Our approach is based on both technical knowledge and practical experience, and we work closely with you to ensure that all relevant aspects of the noise problem are addressed.

Do you have questions or would you like to hear more about how we can help your company deal with noise? Contact Skov Industri for a non-binding interview. Together we can create a better working environment for your employees.